KWIK KHF

Price 10 INR/ Piece

MOQ : 300 Pieces

KWIK KHF Specification

- Capacity

- 25 Kg

- Finishing

- Mirror Finish

- Surface Treatment

- Electropolished

- Weight

- 15 Kg

- Material

- Stainless Steel

- Type

- Hopper Feeding

- Length

- 600 mm

- Diameter

- 200 mm

- Surface

- Polished

- Grade

- 304

- Operating Temperature

- Upto 120°C

- Mounting Type

- Floor Mounted

- Usage/Application

- Industrial, Pharmaceutical, Food Processing

- Automation Grade

- Semi-Automatic

- Thickness

- 1.5 mm

- Shape

- Cylindrical

KWIK KHF Trade Information

- Minimum Order Quantity

- 300 Pieces

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Days

About KWIK KHF

The KWIK KHF is a highlighted solution for elite industrial, pharmaceutical, and food processing environments. Designed with monumental precision, this top-ranking cylindrical hopper feeder boasts a masterful floor-mounted structure made of grade 304 polished stainless steel. Its semi-automatic operation, 1.5 mm thickness, and electropolished mirror finish ensure durability and hygiene. With a robust 25 kg capacity and extensive 600 mm length, this 200 mm diameter unit handles material at temperatures up to 120C. An exceptional deal for manufacturers, service providers, and suppliers across India, offering unparalleled cleanliness and operational efficiency.

Versatile Application and Usage of KWIK KHF

KWIK KHF is specifically engineered for both general and targeted uses in diverse sectors such as pharma, industrial, and food processing. Its semi-automatic operation ensures reliable performance whether handling powders, granules, or bulk solids. With its cylindrical structure and floor-mounted design, it excels in spaces requiring precise material flow. The hoppers site of application includes manufacturing plants, laboratories, and production lines where hygiene, efficiency, and capacity are top priorities.

Main Domestic Market and Packing Details of KWIK KHF

With the arrival of KWIK KHF, facilities across India benefit from its robust capabilities. The product is delivered using secure packaging and dispatch protocols, ensuring its pristine condition upon receipt. Main domestic markets include major industrial and pharmaceutical hubs throughout India. For international clients, the main export markets span Asia, Europe, and the Middle East. Rigorous packing and professional logistics contribute to a streamlined delivery process, guaranteeing reliable performance on arrival.

Versatile Application and Usage of KWIK KHF

KWIK KHF is specifically engineered for both general and targeted uses in diverse sectors such as pharma, industrial, and food processing. Its semi-automatic operation ensures reliable performance whether handling powders, granules, or bulk solids. With its cylindrical structure and floor-mounted design, it excels in spaces requiring precise material flow. The hoppers site of application includes manufacturing plants, laboratories, and production lines where hygiene, efficiency, and capacity are top priorities.

Main Domestic Market and Packing Details of KWIK KHF

With the arrival of KWIK KHF, facilities across India benefit from its robust capabilities. The product is delivered using secure packaging and dispatch protocols, ensuring its pristine condition upon receipt. Main domestic markets include major industrial and pharmaceutical hubs throughout India. For international clients, the main export markets span Asia, Europe, and the Middle East. Rigorous packing and professional logistics contribute to a streamlined delivery process, guaranteeing reliable performance on arrival.

FAQs of KWIK KHF:

Q: How is the KWIK KHF used in industrial and food processing applications?

A: The KWIK KHF is deployed for feeding and handling powdered or granular materials in industrial, pharmaceutical, and food processing environments, ensuring smooth and hygienic transfer to downstream processes.Q: What are the specific benefits of its semi-automatic operation for users?

A: Semi-automatic operation of the KWIK KHF offers a balance between automation and manual control, increasing processing efficiency while maintaining a manageable user interface and ensuring consistent results.Q: What makes the KWIK KHF suitable for pharmaceutical and hygiene-sensitive environments?

A: The KWIK KHF is constructed from 304 grade polished stainless steel with an electropolished mirror finish, which minimizes contamination risk and meets stringent hygiene requirements essential for pharmaceutical and food processing uses.Q: Where is the KWIK KHF typically installed?

A: This hopper feeder is floor-mounted and is commonly installed in production lines, laboratories, or any controlled industrial setting that requires reliable bulk material management.Q: How does the packing and dispatch process ensure safe delivery of KWIK KHF?

A: Carefully designed packaging and professional dispatch protocols protect the KWIK KHF from damage during transit, ensuring the product arrives intact and ready for immediate installation and use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Nylon Anchoring Category

Door Frame Fixing Anchors (KWIK KFS-PRO)

Price 3115 INR / Box

Minimum Order Quantity : 3 Boxes, ,

Color : Red

Material : carbon Steel

Type : Sleeve Anchor

Length : 100 / 120 / 140 Millimeter (mm)

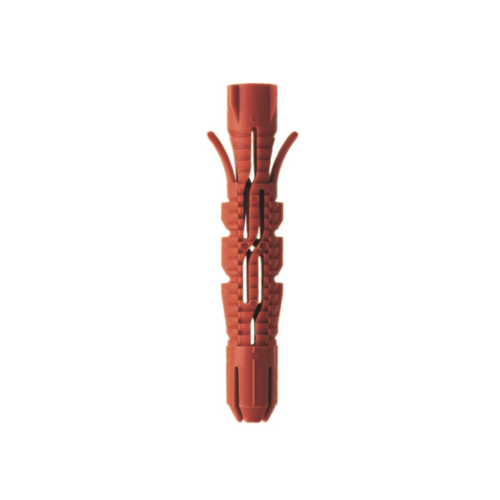

KWIK KNP-L Achor

Price 10 INR / Piece

Minimum Order Quantity : 500 Pieces

Color : Red

Material : Other

Type : Expansion Anchor

Length : 60 Millimeter (mm)

Hammer Fix Anchor

Price 11 INR / Piece

Minimum Order Quantity : 50 Pieces

Color : Silver

Material : Steel

Type : Other

Length : Customized Inch (in)

Door Frame Fixing Anchor-ECO

Price 14 INR / Piece

Minimum Order Quantity : 100 Pieces

Color : Silver

Material : Other

Type : Other

Length : Customized Inch (in)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS